InnoCyclone Technology

We are an industry leader through sustained research to provide better technology at an affordable price and protect our environment through nutrient recovery and reuse.

We have achieved this goal and now work daily to improve the technology continuously.

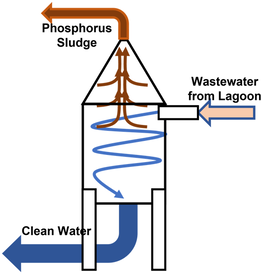

The InnoCyclone is a highly efficient, cost effective system for capturing phosphorus using advanced "separation without filtration" technology.

The separated phosphorus is then dewatered and sent for composing. We compost both alum and ferric precipitated sludges. This allows the phosphorus to find a productive new home and provide renewed value as a non renewable, essential element of life.

This is achieved with a footprint a fraction of the size and cost of other phosphorus capture plants.

The process also significantly reduces both TSS and BOD for improved water quality in the discharged effluent.

We have achieved this goal and now work daily to improve the technology continuously.

The InnoCyclone is a highly efficient, cost effective system for capturing phosphorus using advanced "separation without filtration" technology.

The separated phosphorus is then dewatered and sent for composing. We compost both alum and ferric precipitated sludges. This allows the phosphorus to find a productive new home and provide renewed value as a non renewable, essential element of life.

This is achieved with a footprint a fraction of the size and cost of other phosphorus capture plants.

The process also significantly reduces both TSS and BOD for improved water quality in the discharged effluent.

Most jurisdictions require municipal lagoons to meet strict phosphorus levels of 1mg/L when discharging wastewater into the environment. This is to protect the water quality of of rivers and lakes in our watersheds. Most lagoons do this by the addition of a chemical coagulant to cause the phosphorus to precipitate and settle to the bottom of the lagoon prior to discharge.

This does not remove the phosphorus from the system and over time it causes excess sludge to build up in the cell, thereby reducing the capacity and efficiency of the lagoon. Sludge removal and disposal is a very costly exercise for the municipality.

We are unique in the industry in that we capture the phosphorus, remove it and recover it for future beneficial reuse as a high value fertilizer. Thus providing the most value for our client.

We can provide a mobile system (also a first) or a permanent installation.

This does not remove the phosphorus from the system and over time it causes excess sludge to build up in the cell, thereby reducing the capacity and efficiency of the lagoon. Sludge removal and disposal is a very costly exercise for the municipality.

We are unique in the industry in that we capture the phosphorus, remove it and recover it for future beneficial reuse as a high value fertilizer. Thus providing the most value for our client.

We can provide a mobile system (also a first) or a permanent installation.

RM of Tache: Pilot ProjectRecovering Phosphorus at the Landmark Lagoon |

Phosphorus Recovery

Recovering Phosphorus from Sand Filter Backwash

|

|

Nutrient overloading in Lake Winnipeg has caused severe water quality issues in the lake with excessive algal blooms. In 2016 the Province of Manitoba enacted legislation that requires municipalities to reduce phosphorus levels in wastewater discharging from municipal lagoons. The goal is to reduce the amount of phosphorus reaching Lake Winnipeg in order to help improve the long-term water quality.

Innovative Wastewater SolutionsThe RM of Tache, together with Innovantage Inc., embarked on a pilot project to remove, recover, and reuse phosphorus from the Landmark lagoon. Innovantage is a technology innovation company focused on sustainable development in the municipal sector.

The pilot included multiple trials for capturing phosphorus in wastewater, to help identify a simple cost-effective way for capturing and removing the phosphorus. Trials were run at the Landmark lagoon during the summer of 2021. Next Steps?Since phosphorus is a non-renewable resource and an essential nutrient for plant growth, the second part of the project’s focus was to recover the phosphorus through a composting trial. The aim was to turn the phosphorus precipitated sludge into a high nutrient fertilizer. Innovantage worked with the University of Manitoba to find the optimum parameters for composting the captured phosphorus. The full recovery of the phosphorus for reuse is a breakthrough for growing our sustainable community.

The RM of Tache will continue to investigate the technologies developed to see how they can be used within the current lagoon system for full recovery of the phosphorus. All current long-term planning for our wastewater treatment includes innovative technology development. We look forward to leading the way in wastewater treatment and being good stewards of the environment, thus ensuring the long-term health of Lake Winnipeg for future generations to enjoy.

|

The Town of Altona currently has a unique phosphorus reduction system. Wastewater in pumped from their lagoon system and is then chemically coagulated with Ferric Chloride. The coagulated water is then passed through 4 large sand filters which has the ability to filter and backwash the coagulated phosphorus particles. This backwash is then returned to the primary lagoon cell for precipitation.

Innovantage intercepted this backwash and processed it through an InnoCyclone for complete particle separation. Clean water was returned to the lagoon system and the captured phosphorus rich sludge was further thickened and dewatered in a geotextile bag located in a roll-off container. The sludge could then be hauled to the landfill for for either disposal or for composting. |

| tache_project_brochure.pdf |